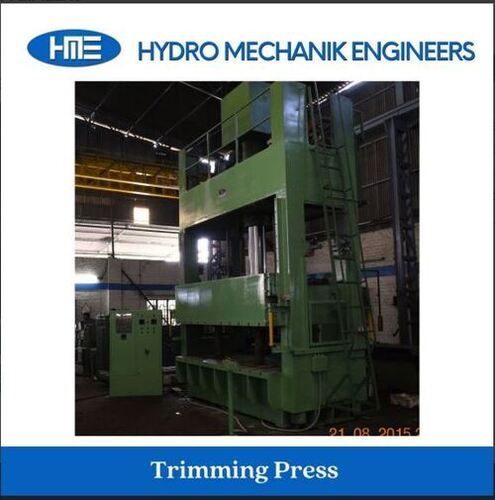

HYDRAULIC TRIMMING PRESS

500000 INR/Number

Product Details:

- Features Sturdy construction, Low maintenance, User-friendly operation, Safety interlocks, Precision trimming

- Temperature Range 5C to 55C

- Sealing Type Double Acting Seals

- Accessories Hydraulic power pack, Control panel, Foot switch, Safety Guard

- Connectivity Type Panel Mounted Controls

- Mounting Type Floor Mounted

- Operating Pressure Up to 250 Bar

- Click to View more

X

HYDRAULIC TRIMMING PRESS Price And Quantity

- 1 Number

- 500000.00 - 2500000.00 INR/Number

- 500000 INR/Number

HYDRAULIC TRIMMING PRESS Product Specifications

- Sturdy construction, Low maintenance, User-friendly operation, Safety interlocks, Precision trimming

- H-Frame (Welded Steel Construction)

- Panel Mounted Controls

- Adjustable (5 30 mm/sec dependent on operation)

- Hydraulic power pack, Control panel, Foot switch, Safety Guard

- Double Acting Seals

- 5C to 55C

- Up to 250 Bar

- Floor Mounted

- 415V AC, 3 Phase, 50 Hz

- Hydraulic Trimming Press

- Electric Motor Driven Hydraulic Power Pack

- 14 to 24 LPM (model dependent)

- Mild Steel

- 25 Ton (variable as per model)

- Suitable for die cutting, trimming of aluminum/zinc/metal castings, and various metal parts

- High operational efficiency

Product Description

Our enterprise has been able to attain a strong foothold in the market by offering the high-utility Trimming Press Machine, Offered in variegated technical specifications. Our clients can avail from us a premium quality range of Trimming Press Machine that are made in accordance with global quality standards and norms. Our expert professional make these products by using only tested raw materials. Esteemed clients can easily avail these products from us at very competitive prices.Advanced Customization Options

The Hydraulic Trimming Press offers customizable ram stroke, platen size, and cycle time to meet unique production needs. Whether trimming intricate die-cast parts or demanding higher speed cycles, the machine can be tailored for optimal results in your application. Adjustable force and speed allow flexibility for different materials and production requirements.

Built-In Operator Safety

This press is equipped with comprehensive safety features such as an emergency stop, pressure relief valve, and an operator safety enclosure. Safety interlocks and foot switch operation further reduce risk, ensuring both the operator and equipment remain safe during intensive trimming operations.

Durable Construction and Performance

Engineered with a sturdy H-frame structure from mild steel and durable powder-coated finish, this press ensures longevity in demanding environments. The double acting seals, high operational efficiency, and noise level under 70 dB result in a machine that is both powerful and pleasant to use in a workshop setting.

FAQ's of HYDRAULIC TRIMMING PRESS:

Q: How does the operator control the Hydraulic Trimming Press?

A: The press can be operated using semi-automatic or manual control modes, with panel-mounted controls and a foot switch for safe and precise operation. This flexibility allows users to select the best mode according to their process needs and safety preferences.Q: What are the main benefits of using this Hydraulic Trimming Press?

A: Key benefits include high operational efficiency, sturdy welded construction, low maintenance, user-friendly operation, and customizable settings for force, speed, and cycle time. Its advanced safety features also ensure a secure work environment.Q: When should the ram stroke or platen size be customized?

A: Customization is recommended when your production requires handling parts with unique dimensions or when specific stroke lengths can improve trimming accuracy and productivity. Custom options enable better adaptation to specialized manufacturing requirements.Q: Where can this press be installed?

A: The press is designed for floor mounting and is suitable for installation in manufacturing plants, foundries, or metalworking workshops. Its 415V AC, three-phase power requirement makes it compatible with standard industrial power setups in India and similar regions.Q: What is the process for trimming metal parts using this machine?

A: Place the workpiece securely on the platen, select the appropriate cycle mode, and use the control panel or foot switch to activate the press. The hydraulic system applies the programmed force and motion to trim or cut the part according to tooling specifications.Q: How does the press ensure operator safety during use?

A: Operator safety is maximized through emergency stops, a pressure relief valve, safety enclosure around the operating area, safety interlocks that prevent accidental starts, and a foot switch for hands-free activation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

HYDRO MECHANIK ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |